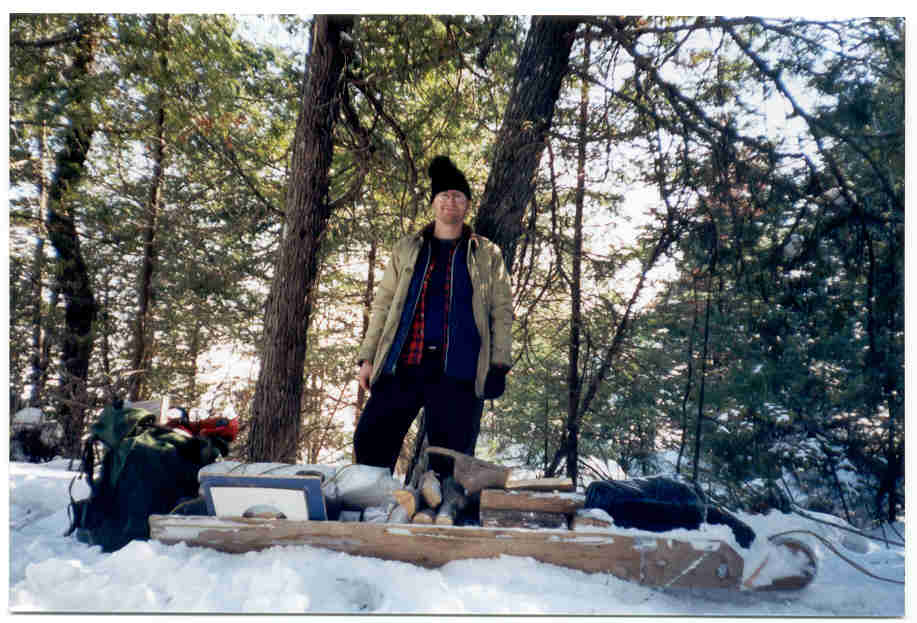

This winter shelter cost under $50cdn, weighs not much, and works well. Rope around two trees 18 feet apart provides structure and support for an 18 foot long plastic tube. The tube is made of two sheets of 6mil vapour barrier welded together. Morning light comes through to greet me. The stove is a length of 8 inch diameter stovepipe with end caps, and the stack is 4 inch diameter vent ducting. Burn off the galvanized (lead-tin) coating prior to use. The ends of the plastic tent tube are closed with clips or crude stitching with the bottom open to feed the stove, and occupants, with fresh air. Old ski poles angling from the rope rails keep the walls tented out. I get a 30C temperature differential inside versus outside. With a hole in the floor I let the stove melt to the ground. Condensate inside can be wiped with a rag, and only needs to be done once early on. The stove is situated to give a bedroom at the back and a storage antichamber at the front entrance. The exhaust goes through a wood sheet with a perfectly fitting inner metal sheet. Melting plastic was a concern but after various extreme design experiments, and then overnight testing, I found no hint of melting...there is wide safety margin. As you would expect, the stove is good for heating soup or making coffee. I find Thermarests are cold, uncomfortable and don't pack tightly. Air mattresses have a shorter life and ultimately cost me more, but I spare no expense when it comes to sleeping comfort. 3 minutes to blow up and one to suck flat. The woodstove acts like a lung to bring in fresh air.

If the stove exhaust were blocked, the smoke is not odourless...it is acrid nasty stuff that will rip at your nose and bite at your throat...so you wake up and get out rather than die an odourless C02 death. Next to electric heat, woodstoves are the only other heat source I trust.

Plastic welding:

Use heavy duty hot glue. It has the most thermal heat

capacity for welding. Ensure the weld by squeezing the

sheets with a cloths iron. Use a sheet of wood underneath

and a moist cloth above to avoid making holes. Use as little glue

as possible to fuse the sheets together. Extra glue offers

no advantage, and the disadvantage of stiffness. Welding

works well, while no glue exists that works at all.

Plumbing solvents also don't work.

Stove Door.

Use the curvature to advantage by using a door which is

just sheet steel which wraps across the opening. I use

a buckle scheme similar to the lid fastener band on many

oil drums. Operate any woodstove with work gloves to avoid

splinters and burns.

Firestart:

Cut a wax-sawdust firelog into 40 cubes with a circular

saw. One cube obviates all kindling and will get even

cordwood going. The Light & forget firestart method.

Heat Shield Board:

Use eye hooks on the edges and feed the rope through

them. Now the board slides along the rope rails wherever

it needs to be.

Clips:

I use big black metal office supply clips from Office

Depot. Use liberally.

Vapour Barrier:

4mil is a lighter weight possibility but I like the heavy

6mil stuff. Folding is an art. A magic marker mark

declaring "top" & "front" is a good idea. Orient so the

welds shed outside water rather than trap water.